光伏组件Kiwa认证

目前中国以其完善的产业链和巨大产能,已经成为光伏组件全球第一生产大国,产品畅销于全球各个市场,并且以其优良的品质和有竞争力的价格日益成为客户的首选。

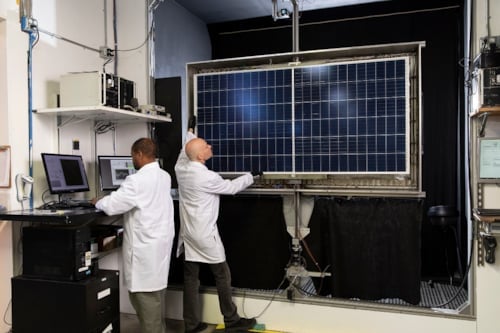

KIWA集团为广大企业提供光伏组件的KIWA认证,KIWA集团目前在意大利和中国建有完备的光伏组件检测实验室,为客户提供KIWA Solar Mark认证,KIWA 太阳能认证标志是光伏组件高品质的象征。

我们为核工业市场提供工艺设备检查服务,以确保加压设备和管道的安全。我们的检查依据包括国家和国际的法律要求、您提供的工艺信息、无损检测(NDT)以及 Kiwa 的经验知识。评估会考虑以下方面:

得益于现代技术,新的先进检测、检验和认证核设备的技术不断涌现。Kiwa 的专家熟悉技术及材料检验领域的最新发展。我们提供的服务包括无人机检测、泄漏检测、生命周期分析以及工艺和自动化安全服务。

在材料检验方面,我们采用破坏性测试(DT)、损伤检查和使用寿命分析。作为您前进的伙伴,我们帮助您提升业务。我们共同规划最佳的发展路径。这一切都是为了确保安全、质量和健康,并尽量减少您和您公司的停机时间。

我们的项目组合中包含大量的风险分析。从定量风险分析到工艺安全分析:我们清楚哪种类型最适合您。在下面的列表中,您可以看到我们所执行的分析的简要概述。

Kiwa有能力支持大型项目,例如装置检修、改造和新建项目。我们在整个北欧地区拥有庞大的国际检查员和操作员团队。凭借这种覆盖范围,我们能够为该地区的大型资本项目提供全方位的检验服务,包括供应商检验、质量保证/质量控制、压力设备检验、焊工认证、材料测试和无损检测。

有任何疑问或需要报价,您都可以通过右侧表格与我们联系。